Commercial & Industrial

At Culligan, we specialise in delivering innovative solutions tailored to meet the unique water needs of commercial and industrial settings.

At Culligan, we specialise in delivering innovative solutions tailored to meet the unique water needs of commercial and industrial settings.

Culligan experts provide tailored water treatment solutions for a range of industries and applications.

We offer comprehensive solutions, including conditioners, softeners, and filtration systems, designed to meet the unique needs of commercial and industrial settings.

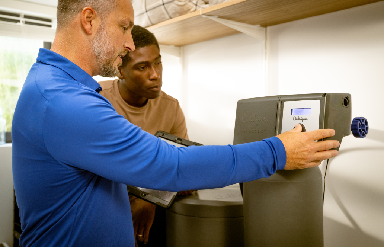

Benefit from our expert installation, commissioning, and maintenance services, ensuring seamless integration and optimal performance of your water treatment systems

With over 85 years of experience in the water treatment industry, trust Culligan for reliable solutions backed by unparalleled expertise and a commitment to customer satisfaction.

Culligan Commercial & Industrial UK leverages its extensive worldwide water treatment experience to deliver affordable and efficient water treatment solutions tailored to the needs of UK businesses.

We are an integral member of the global Culligan family. We are dedicated to improving water quality for clients worldwide.

With a comprehensive range of water softeners, filtration systems, and industrial treatment solutions, we are proud to set the standard in the water treatment industry.

We are committed to providing cutting-edge products and water solutions that benefit our customers, while prioritising environmental sustainability.

Drawing on our global expertise in water treatment, Culligan Commercial & Industrial provides cost-effective solutions for businesses across manufacturing, hospitality, and leisure sectors.

From manufacture to installation and ongoing service, we offer a comprehensive solution ensuring peace of mind for our customers.

Whether you require scale prevention for pipework and boilers or specialised borehole water treatment, trust in our efficient and reliable solutions.

Culligan prevents legionella outbreaks in cooling towers with thorough inspection and maintenance.

Tailored treatment systems maintain water quality, preventing scaling and contamination in cooling systems.

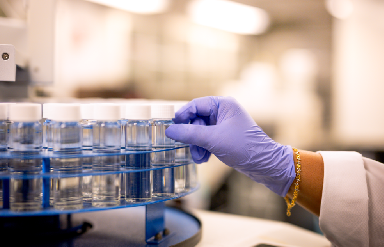

Culligan’s advanced disinfection systems ensure water safety and surpass industry standards.

Across industries, Culligan employs a personalised strategy to deliver tailored, comprehensive, and budget-friendly solutions to meet each customer's unique needs and challenges.